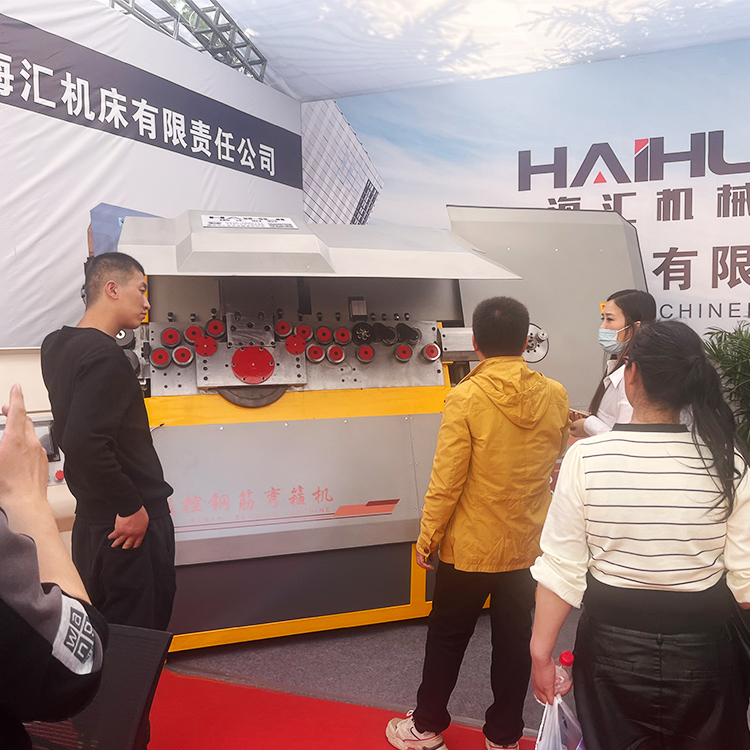

Efficient output: Fully automatic hoop reinforcement machine. Straightening and bending hoop plate reinforcement integrated machine

In the bustling world of construction and steel - bar processing, efficiency is the name of the game. Two remarkable pieces of equipment that have been revolutionizing the industry are the Fully Automatic Hoop Reinforcement Machine and the Straightening and Bending Hoop Plate Reinforcement Integrated Machine. These machines are not just tools; they are powerhouses that drive high - speed, high - quality production.

The Fully Automatic Hoop Reinforcement Machine is a paragon of modern engineering. Its automated system is a cut above the rest, precisely controlling every stage of hoop production. From the moment the steel bar enters the machine, sensors and advanced algorithms work in tandem. They determine the exact length, the angle of bends, and the overall shape of the hoop with surgical precision. This level of accuracy is not just a luxury but a necessity in construction, where even the slightest deviation in hoop dimensions can compromise the structural integrity of a building. Whether it's for a simple residential project or a complex commercial skyscraper, the machine ensures that each hoop is identical in quality and specification.

When it comes to output, this machine is in a league of its own. Powered by high - torque motors and a seamless feeding mechanism, it can produce hoops at an astonishing rate. The continuous operation of the machine, without the need for frequent manual interventions, significantly boosts productivity. It can churn out a large number of hoops in a short span of time, reducing the overall production time for any construction project. This speed is a boon for contractors who are constantly under pressure to meet tight deadlines. It allows them to complete projects more quickly, thereby increasing their capacity to take on more jobs and grow their business.

Despite its high - tech and complex functionality, the Fully Automatic Hoop Reinforcement Machine is designed with the user in mind. The control panel features an intuitive interface that is easy to navigate. Operators, regardless of their level of technical expertise, can quickly understand and input the required settings for hoop production. The machine also provides real - time feedback on the production process, such as the number of hoops produced, the speed of operation, and any potential errors. This user - friendliness not only makes the machine accessible but also reduces the training time required for new operators, further enhancing the overall efficiency of the production process.

### 多功能一体化优势

The Straightening and Bending Hoop Plate Reinforcement Integrated Machine is a revolutionary concept in steel - bar processing. By integrating the functions of straightening, bending, and hoop and plate reinforcement formation into a single unit, it eliminates the need for multiple machines and the associated transfer of materials between them. This seamless integration streamlines the production process, reducing both time and effort. The machine starts by straightening the steel bars to a perfect level, ensuring that they are free from any kinks or bends. Then, it proceeds to bend the bars into the desired shapes, whether it's circular hoops, rectangular plates, or more intricate configurations, all in one continuous operation.

One of the key strengths of this integrated machine is its ability to be customized according to specific project needs. Operators can easily adjust the settings to produce different sizes, shapes, and thicknesses of hoop and plate reinforcements. For example, in a building project where different types of reinforcements are required for different structural elements, the machine can be quickly reconfigured to meet these diverse requirements. This flexibility makes it an invaluable asset for construction companies that handle a wide range of projects, from small - scale renovations to large - scale infrastructure developments.

Throughout the production process, the Straightening and Bending Hoop Plate Reinforcement Integrated Machine maintains a high level of quality control. The straightening mechanism uses precision - engineered rollers and sensors to ensure that the steel bars are straightened to the exact specifications. The bending process is equally precise, with the machine capable of creating consistent and accurate bends every time. This attention to detail at every stage of production results in high - quality hoop and plate reinforcements that meet or exceed industry standards. The end - products are not only strong and durable but also contribute to the overall safety and stability of the construction projects they are used in.

In conclusion, the combination of the Fully Automatic Hoop Reinforcement Machine and the Straightening and Bending Hoop Plate Reinforcement Integrated Machine offers a comprehensive solution for efficient steel - bar processing in the construction industry. Their advanced features, high - speed production capabilities, and user - friendly design make them indispensable tools for any construction company or steel - bar fabricator looking to optimize their operations, increase productivity, and deliver high - quality projects.

WeChat scan code

WeChat scan code

support hotline13932960232

mobile phone+86 139 3296 0232

CNC steel bar bending hoop machine Add:Add: Dengqiao Haihui Machine Tool, Tiankou Town, Renze District, Xingtai, Hebei, China. Xingtai Haihui Machine Tool Co., Ltd